Turning and milling capabilities serve to projects from small businesses to industry giants, allowing us to provide top-quality solutions. With state-of-the-art technology at our disposal, we achieve both precision and competitive pricing.

By leveraging advanced technology and a skilled team, we maintain high precision and stability, delivering desired solutions within our clients expectations. Our continuous investment in technology and personnel reflects in the exceptional solutions we offer. We prioritize cost-effectiveness in our workflow and ensure responsible utilization of time and resources for each project.

Experience has led us to effectively lower the production costs. Quality, less waste and more environment friendly are top priorities in our business evolution. To achieve this, we invested in superior equipment and human resources while maintaining competitive prices.

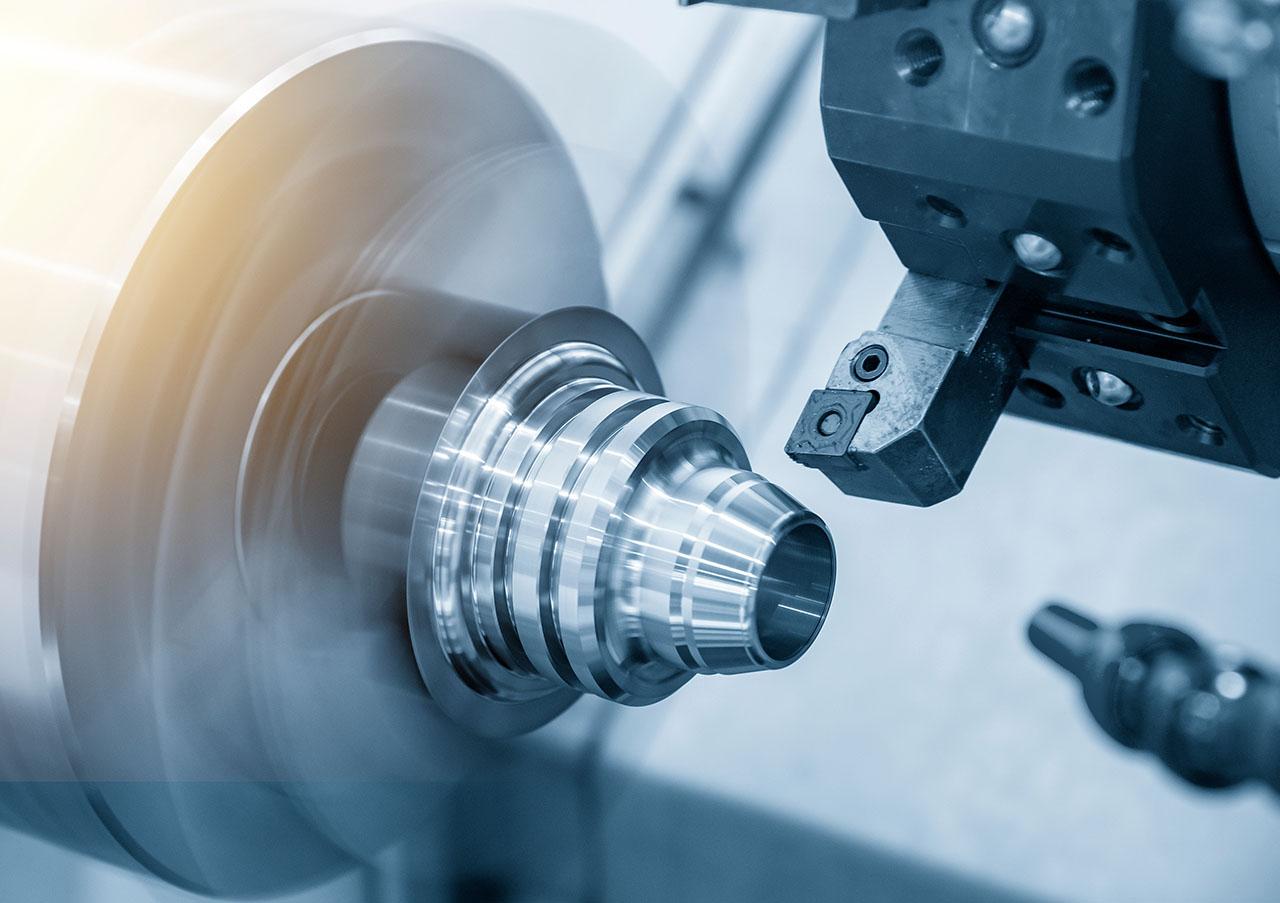

CNC Turning & Milling

CNC Turning is the ideal solution when aiming to avoid challenging geometries like very long and thin structures, with reduced complexity and less material removal.

CNC Milling plays a pivotal role in achieving cost reduction objectives, allowing us to exercise precise control over material removal, minimize complexity, avoid intricate features, and maintain simplicity in shapes.

Strategic use of CNC Turning and Milling processes, contributes to our overall commitment to cost-effectiveness throughout the workflow.

Processing & Results

As the cutting tool rotates, a computer precisely controls the vertical motion along the Z-axis of the cutter and the horizontal motion along the X and Y axes of the material block. In the typical setup, the cutting tool revolves around an axis perpendicular to the table that securely holds the material for cutting. A cutting tool extends downward from a rotating spindle, while a block of material is positioned on a movable table beneath the cutter. As the cutting tool rotates, a computer precisely controls the vertical motion along the Z-axis of the cutter and the horizontal motion along the X and Y axes of the material block.

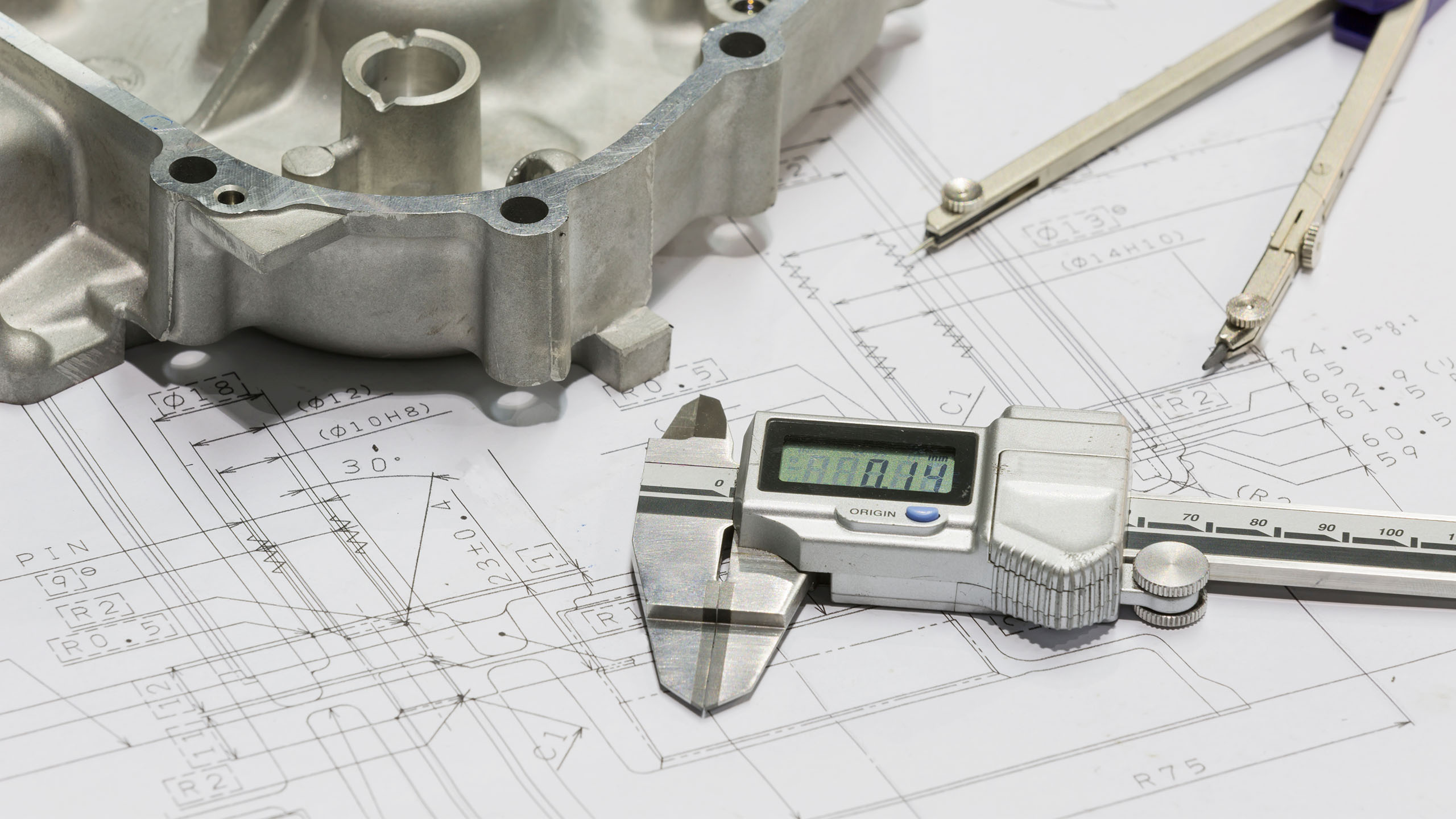

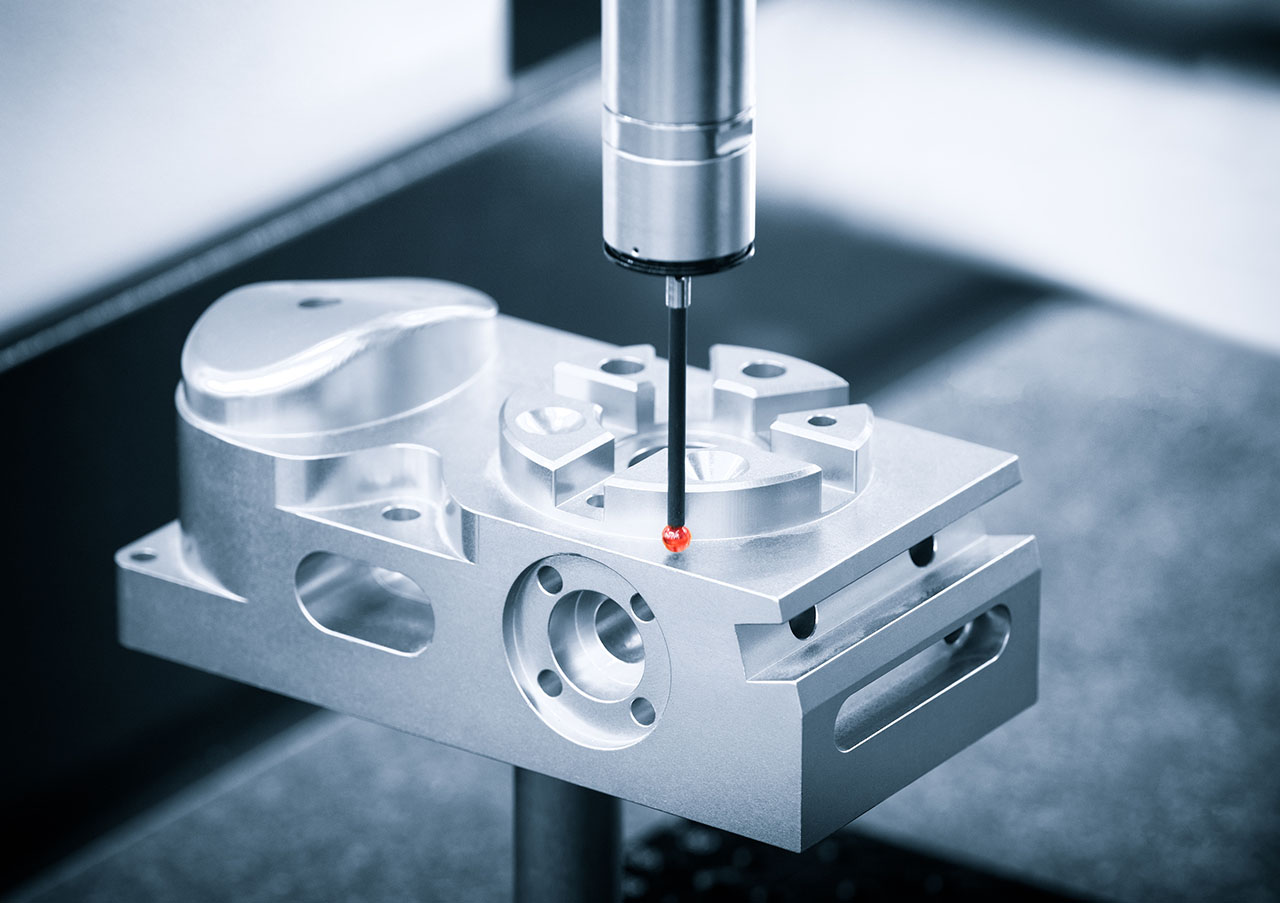

Quality Control

Our progress has been driven by a combination of our strong work ethic, unwavering dedication, and commitment to quality. We firmly believe in the importance of delivering flawless products. To ensure precision and meet our clients' specific requirements, we employ rigorous quality checks. Every product undergoes meticulous measurement and examination, adhering to the precise specifications outlined by the client. This precision is achieved through accurate measurements using advanced tools such as the CMM (Coordinate Measuring Machine) and the portable CMM arm, allowing us to maintain the highest level of quality control.

VISIT OUR FACTORY FOR MORE